Yi magana game da misali ɗaya na jiyya na saman a cikin 'yan kwanakin nan.

An ba mu amana don ƙira kuma mun yi sabon ƙirar magana mai magana. Ana amfani da maganadisu a tashar jiragen ruwa don gyara jirgin ruwa da kayan aiki.

Al'ada tana ba da girman samfurin da buƙatun ƙarfin ja.

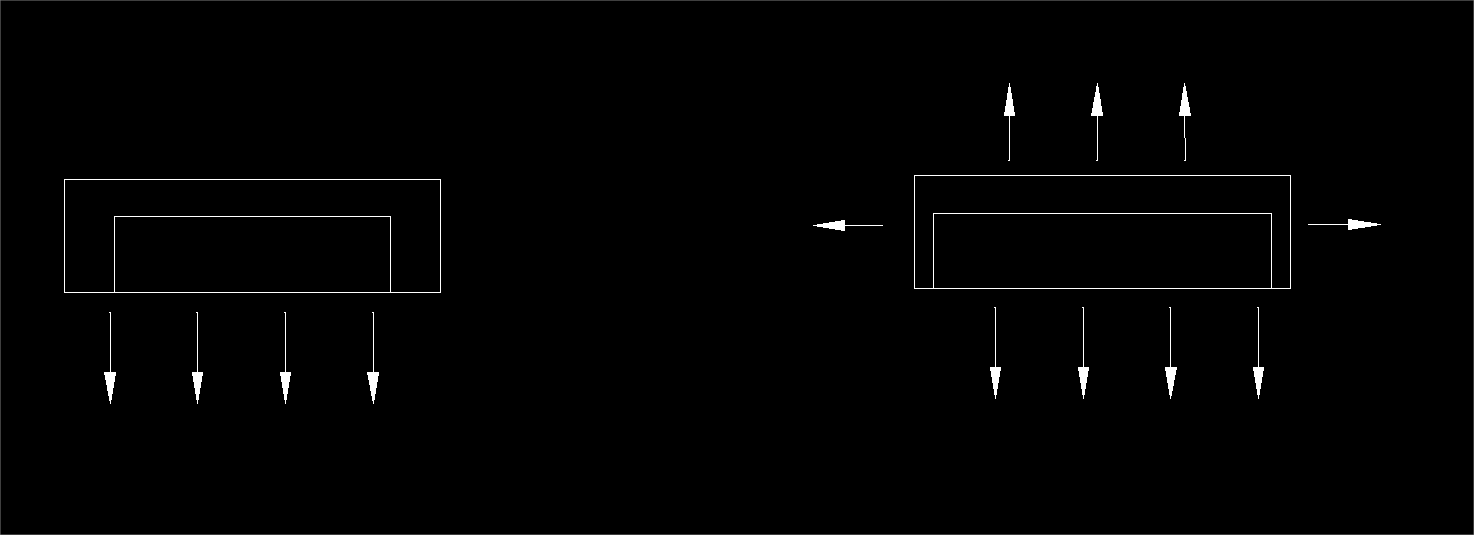

Da farko, muna ƙayyade girman maganadisu na anka. Ɗaya daga cikin maɓalli don ƙarfin ja shine cewa kana buƙatar samun isassun kauri na harsashi ko kuma ikon magenci zai rabu da sauran sassan harsashi maimakon tahn sanya dukkan iko a gefen da muke so. Kamar hoton da ke ƙasa ya nuna, waɗannan tukunyar maganadisu guda biyu suna da girman guda ɗaya, amma na dama yana da babban maganadisu. Shin wanda ya dace zai sami mafi kyawun ƙarfin maganadisu? Ba shakka. Sanadin wani bangare na wutar lantarki ya bi ta sauran bangarorin da ke yanke kauna. Yayin da hagu yana da keɓe mai kyau, duk ƙarfin maganadisu yana mayar da hankali gefe ɗaya wanda ke sa ƙarfin jan ya kasance a cikin mafi girma.

Mu dawo kan magnet din anga, mun yi wani module ya sanya faifan magnet a kasa, muka gwada karfinsa. Ya nuna cewa zai iya samar da fiye da 1000kg na iko.

Abokin ciniki kuma ya yi farin ciki da cewa mun yi samfurin da sauri kuma ba mu ɓata ƙarfin maganadisu da yawa ba, yayin da suke so su ƙara rayuwar sa. Suna son sakamakon gwajin feshin Gishiri zai kasance fiye da sa'o'i 300.

A halin yanzu saman jiyya na maganadiso ne mai rufi Ni, Grade 5 electroplating. Ko da wannan, sakamako mafi kyau shine cewa ba zai iya kiyaye tsatsa ba har tsawon sa'o'i 150.

Hanya ɗaya don yin haka ita ce sufa robar don rufe murfin Ni. Rubber abu ne mai kyau na keɓancewa, wanda zai iya yanke jigilar ruwa da atom ɗin ionized, shima yana da kyau a juriyar abrasion.

Koyaya, cladding yana da kauri! Musamman ga roba. Kauri daga cikin roba ne 0.2 ~ 0.3mm, yayin da karya ikon fadowa zuwa kasa da 700kg.

Wannan kauri ya sa aikin ya bambanta sosai, idan muna so mu sanya shi kiyaye ƙarfin ja iri ɗaya, muna buƙatar ƙara girman magnet da harsashi. Wannan zai kara yawan farashi. Yi la'akari da yanayin rayuwa da duka farashi. Babu shakka, ba shine mafi kyawun zaɓi ba.

Wata hanya ita ce ƙara anobe rob don haɗawa da maganadisu, za mu iya kare shi ta hanyar hadaya anode. Duk da haka, yana buƙatar yin rami a cikin harsashi don sararin samaniya na itacen anode, wanda ke buƙatar sabon tsari. Don haka, zaɓi ne mai yuwuwa.

Hakanan, harsashi yana da matsalar tsatsa shima. Mun yanke shawarar fesa fenti akan harsashi. Amma fesa kamar roba mai rufi, shima yana da kauri. Dangane da gwajin, fenti yana rage 15% ƙarfin ja na anka.

Don haka a ƙarshe mun yanke shawarar yin sutura ta Cr, wanda zai iya kare harsashi kuma ya kiyaye magnet yana da ƙaramin tazara daga harsashi don tabbatar da cewa ƙarfin maganadisu ba zai ragu da yawa ba.

Saboda haka, shi ne ma'auni tsakanin electroplating lalata juriya da Magnetic ja karfi, muna bukatar mu nemo hanya mafi kyau ga samfurin la'akari da rayuwarsa da kuma kudin.

Lokacin aikawa: Agusta-24-2024